GUIDELINES FOR EX-SITU TREATMENT OF SOIL BIOREMEDIATION

The main area to consider is that you must get the solution of microbes and nutrient in contact with the contaminant. If you have a shallow penetration of a contaminant such as a petroleum product, say 3-4 inches, you will get a quicker clean-up if you can disturb the soil, that is aerate and mix. This can be achieved with a shovel, disked which will penetrate 6-8 inches (this is a farming device, pulled by a tractor), or a root rake. With anything less than 3-4 inches, saturating the surface will usually suffice.

For deeper penetrations, the same principal applies though heavier duty equipment is needed. A back hoe which can toss the soil to aerate and mix it; a bulldozer with ripper blades for large sites is excellent; even a portable conveyor belt where the soil is loaded at the lower end and “flung” out of the upper end will accomplish the mixing and aeration. As the soil is moving up the conveyor belt, a spray inoculation will achieve good coverage.

MOISTURE LEVELS FOR EX-SITU SOIL BIOREMEDIATION

You must maintain a moisture level range of between 15% and 20% as a minimum. Oil on soil acts as waterproof so make sure you penetrate that waterproof barrier. A 20% moisture level in soil occurs when you can make a mud ball with your hands. Higher than 20% is fine; remember these microbes can treat contaminated water where the moisture level is 100%. If the moisture level drops, all is not lost as the microbes form spores, that is go inert until they get more water to activate them.

SUMMARY OF EX-SITU SOIL BIOREMEDIATION

Procedure is to Mix, Aerate, and Hydrate.

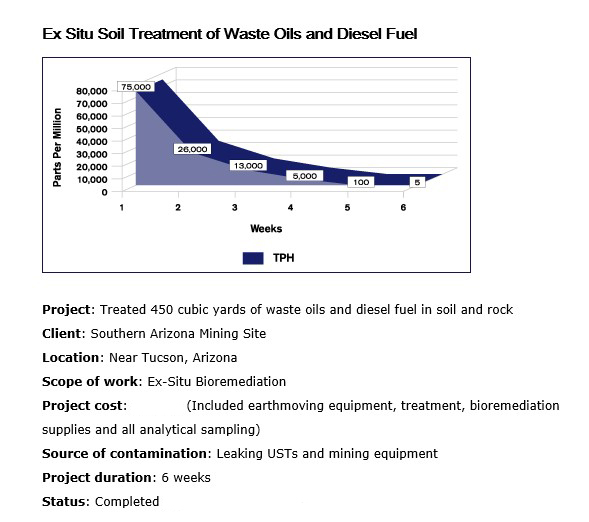

EXAMPLE OF EX-SITU SOIL BIOREMEDIATION

INOCULATION GUIDELINES AND A PASSIVE IN-SITU BIOREMEDIATION SYSTEM

Nothing will happen in a Bioremediation Treatment unless you can get the microbes and nutrient in contact with the contaminant. You should strive for a moisture level of at least 20%.

A good rule is to set up inoculation points at 6 foot intervals in closely packed soil. So drill at 6’ centers and inoculate with the mixture of microbes and nutrient and you will get a good horizontal overlap. Frequently, the inoculant will overflow out of the adjacent hole which is a good indication that there is excellent horizontal disbursal.

Review of some basic soil moisture facts: a cubic yard of soil contains the equivalent of 201 gallons of water. 20% of that is slightly more than 40 gallons. So in perfectly dry soil, you would need 40 gallons to achieve a 20% moisture level.

Most soil already contains a moisture level, so you may need less than 40 gallons and that can be easily calculated.

The selection of the drill type is important. While a Geo-Probe is a useful and inexpensive piece of equipment, it is important to know that in closely packed soil, the drill can actually pack the soil around the bore hole even tighter, and can in fact pack the soil so tight that fluid can’t penetrate.

This makes it difficult to properly disburse the microbes, nutrient and the water.

BIOREMEDIATION IN-SITU PASSIVE SYSTEM

This simple, passive, gravity system works really well when used in conjunction with microbes. In one of our popular products, we grow our microbes on and in small carbon pellets. The resultant plate counts are enormous. Since a tablespoon of carbon pellets contain the surface area of a football field, you can imagine the nooks and crannies available for the microbes to live and breed in.

When you are drilling your inoculation points (remember 6 foot centers) simply line the holes with slotted PVC, capped at the bottom end with the slots placed in the contaminated zone, and leave the surface end either slightly recessed if you need to drive over the property (as in a gas station) or leave the stubs exposed. Either way, you can cover the top end with removable caps so you can continue to make inoculations during the life of the project.

Before insertion of the slotted PVC pipes, or right after insertion, add some of the dry carbon pellets, about 6-8 inches from the bottom. This will contain billions and billions of microbes perfectly at home in the carbon. They will continue to grow and multiply when you add water and nutrient to each PVC. The carbon pellets do not dissolve and merely are the carriers for the billions of microbes.

The microbes will last month after month and when you add more water and nutrient, there will be so many that the excess will sheer off and make their way through the slots in the PVC and disburse into the site. You can keep the site moist, well supplied with nutrient, and continually add more mixture of microbes and nutrient whenever you can.

One man can keep a site active once every week or two. You can even inject the solution of microbes under pressure for even better horizontal disbursement.

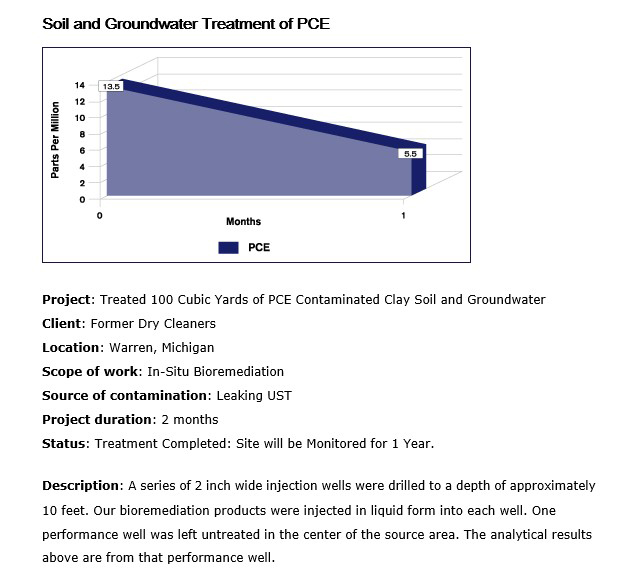

EXAMPLE OF IN-SITU BIOREMEDIATION PASSIVE SYSTEM