- Product Details

Zimbabwe Chrome Ore Mine Large Quantity Ready to Ship

Loose loading in Containers.

24 Tons per 20' Container.

MOQ 1000 Tons.

Following South Africa, Zimbabwe enjoys the world’s second-largest high-grade chromium ore deposit of approximately 10 billion tonnes, around 12% of global reserves, according to the Zimbabwean Ministry of Mines and Mining Development.

But the chrome-rich nation produced just 866,000 tonnes chrome ore and concentrate in 2019, accounting for 2.5% of global output that year, according to International Chromium Development Association.

Chrome Ore Composition

|

Item |

Unit |

Index |

|

Cr2O3 |

% |

46.0min |

|

SiO2 |

% |

1.0max |

|

FeO |

% |

26.5max |

|

CaO |

% |

0.30max |

|

MgO |

% |

10.0max |

|

Al2O3 |

% |

15.5max |

|

P |

% |

0.003max |

|

S |

% |

0.003max |

|

Cr/Fe |

/ |

1.55:1 |

|

Bulk Density |

g/cm3 |

2.5-3 |

|

Color |

/ |

Black |

|

PH |

/ |

7-9 |

|

The amount of the acid |

/ |

2ML(MAX) |

|

Percent Soil |

% |

0.1max |

|

Percent Moisture |

% |

0.1max |

|

The Sintered |

|

1600 |

|

Percentage of Free Acid Present in the Sand |

% |

0 |

|

Filling Density |

g/cm3 |

2.6 |

|

Sintering Point |

|

1800min |

|

Melting Temperature |

|

2180 |

About Chrome Ore

Chromium ore, also known as chromite, is also used in the refractory and metallurgical industries. Chromite is an oxide mineral that an iron chromium oxide with formula: FeCr2O4. Its resistance to fire of up to 1900 °C, good gas permeability and low thermal expansion combined with good thermal conductivity make this raw material an effective barrier to molten metal compared to other moulding sands. In contrast to the alternative quartz sand, there is no risk of developing silicosis when using the raw material chrome ore sand. Chrome ore sand is obtained from chromite (chrome iron ore), which is processed into chromite sand with the aid of liquid binders after extraction from natural deposits.

Chromite minerals are mainly found in mafic-ultramafic igneous intrusions and are also sometimes found in metamorphic rocks. The chromite minerals occur in layered formations that can be hundreds of kilometres long and a few meters thick. Chromite is also common in iron meteorites and form in association with silicates and troilite minerals. Chromite is a crystalline mineral composed primarily of iron(II) oxide and chromium(III) oxide compounds. It can be represented by the chemical formula of FeCr2O4. It is an oxide mineral belonging to the spinel group. The element magnesium can substitute for iron in variable amounts as it forms a solid solution with magnesiochromite (MgCr2O4). A substitution of the element aluminium can also occur, leading to hercynite (FeAl2O4). Chromite is the most important ore of chromium. Crystals are uncommon, but when found they are octahedral. Chromite is usually massive or in the form of lenses and tabular bodies, or it may be disseminated as granules. It is sometimes found as a crystalline inclusion in diamond. Chromite is dark brown to black in color and can contain some magnesium and aluminum. Chromite is most commonly found as an accessory mineral in iron- and magnesium-rich igneous rocks or concentrated in sediments derived from them. It occurs as layers in a few igneous rocks that are especially rich in iron and magnesium. Almost pure chromite is found in similar layers in sedimentary rocks. The layers are preserved when the sedimentary rocks metamorphose to form serpentinite. Referred to as chromitites, these rocks are the most important ores of chromium. The weathering of chromite ore bodies can also lead to its concentration in placer deposits.

Chromite Physical Properties

| Crystal habit | Octahedral rare; massive to granular |

| Color | Black to brownish black; brown to brownish black on thin edges in transmitted light |

| Streak | Brown |

| Luster | Resinous, Greasy, Metallic, Sub-Metallic, Dull |

| Cleavage | None Observed |

| Diaphaneity | Translucent, Opaque |

| Mohs Hardness | 5,5 |

| Crystal System | Isometric |

| Tenacity | Brittle |

| Density | 4.5 – 4.8 g/cm3 (Measured) 5.12 g/cm3 (Calculated) |

| Fracture | Irregular/Uneven, Hackly, Sub-Conchoidal |

| Parting | Parting may develop along {111} |

| Other characteristics | Weakly magnetic |

Chromite Optical Properties

| Type | Isotropic |

| Color / Pleochroism | Non-pleochroic |

| RI values: | n = 2.08 – 2.16 |

| Twinning | On {111} |

| Birefringence | 0.0 |

| Relief | Very High |

Chromium Mining

The only ore of chromium is the mineral chromite and 99 percent of the world’s chromite is found in southern Africa and Zimbabwe. The mining method used for extracting chromite depends greatly on the characteristics of the deposit. These characteristics include whether it is stratiform or podiform, high grade or low grade, subsurface or near surface, or massive or disseminated. Because surface mining typically is less expensive than underground mining, it is preferred, but not always possible. Like mining, beneficiation (processing, crushing, separating, smelting, refining, etc.) for chromite depends on the characteristics of the ore deposit and on the mining methods used. For example, an operation extracting only high-grade ore may require only hand sorting and screening. Beneficiation is necessary when chromite mineral is mixed with other minerals because of geologic conditions or when mechanized mining methods are nonselective.

The most important applications of chromium ores are in the manufacture of stainless steel, gray cast iron, iron-free high-temperature alloys, and chromium plating for surface protection. Chromite today is mined particularly to make stainless steel through the production of ferrochrome (FeCr), which is an iron-chromium alloy. The chemical industry uses chromium ores in the production of chromium compounds for the tanning of leather. Chromium is used with various other metals to give hardness to steel, also as a plating material because of its non-corrosive nature. Chromite bricks are used to a considerable extent as linings for metallurgical furnaces, because of their neutral and refractory character. The bricks are usually made of crude chromite and coal tar but sometimes of chromite with kaolin, bauxite, or other materials. Chromium is a constituent of certain green, yellow, orange, and red pigments and of similarly colored dyes. The major markets for chromium materials are chromium chemicals, ferroalloys and metal. The primary uses of chromium are in stainless steels, nonferrous alloys and chromium plating. Chromite ore can also be roasted to make sodium dichromate, which is subsequently converted to chromium chemicals used in pigments and metal coatings. Chromium is also an important component in refractories, foundry applications, and as a nutrient. Trivalent chromium (Cr(III)) is an important micronutrient and improves the efficiency of insulin in individuals with impaired glucose tolerance. Meats, vegetables, fruits and grains are metabolic sources of chromium.

Chromium Uses:

- Used to harden steel, to manufacture stainless steel and to form alloys

- Used in plating to produce a hard, beautiful surface and to prevent corrosion

- Used to give glass an emerald green colour. it is responsible for the green colour of emeralds and the red colour of rubies

- Wide use as a catalyst

- Dichromites such as K2Cr2O7 are oxidizing agents and are used in quantitative analysis and also in tanning leather

- Lead chromate as chrome yellow is a pigment

- Compounds are used in the textile industry as mordants

- Used by the aircraft and other industries for anodising aluminum

- The refractory industry uses chromite for forming bricks and shapes, as it has a high melting point, moderate thermal expansion, and stable crystalline structure

- Tanning leather

Ferro Chrome as steel additive to produce a variety of high strength, corrosion resistance, wear resistance, high temperature resistance, oxidation resistance of special steel, such as stainless steel, acid-resistant steel, heat resistant steel, ball bearing steel, spring steel, tool steel.Chromium metal is mainly used for smelting special alloy with cobalt,nickel, tungsten and other elements. These special steels and special alloys are indispensable materials for the production of guns, missiles and rocket ships in aviation, aerospace, automobile, shipbuilding and national defense industries.

Chrome Grade Specification

|

Grade |

Chemical Composition(%) |

|||||

|

Cr |

C |

Si |

P |

S |

||

|

Micro carbon |

Grade 1 |

58-68 |

0.03-0.15 |

1.0-2.0 |

0.03-0.06 |

0.025-0.03 |

|

Grade 2 |

63-68 |

0.03-0.15 |

1.0-2.0 |

0.03-0.06 |

0.025-0.03 |

|

|

Low carbon |

Grade 3 |

58-68 |

0.25-0.5 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

Grade 4 |

63-68 |

0.25-0.5 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

|

Medium carbon |

Grade 5 |

58-68 |

1.0-4.0 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

Grade 6 |

63-68 |

1.0-4.0 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

|

High carbon |

Grade 7 |

58-68 |

4.0-10.0 |

3.0-5.0 |

0.03-0.06 |

0.03-0.06 |

|

Grade 8 |

63-68 |

4.0-10.0 |

3.0-5.0 |

0.03-0.06 |

0.03-0.06 |

|

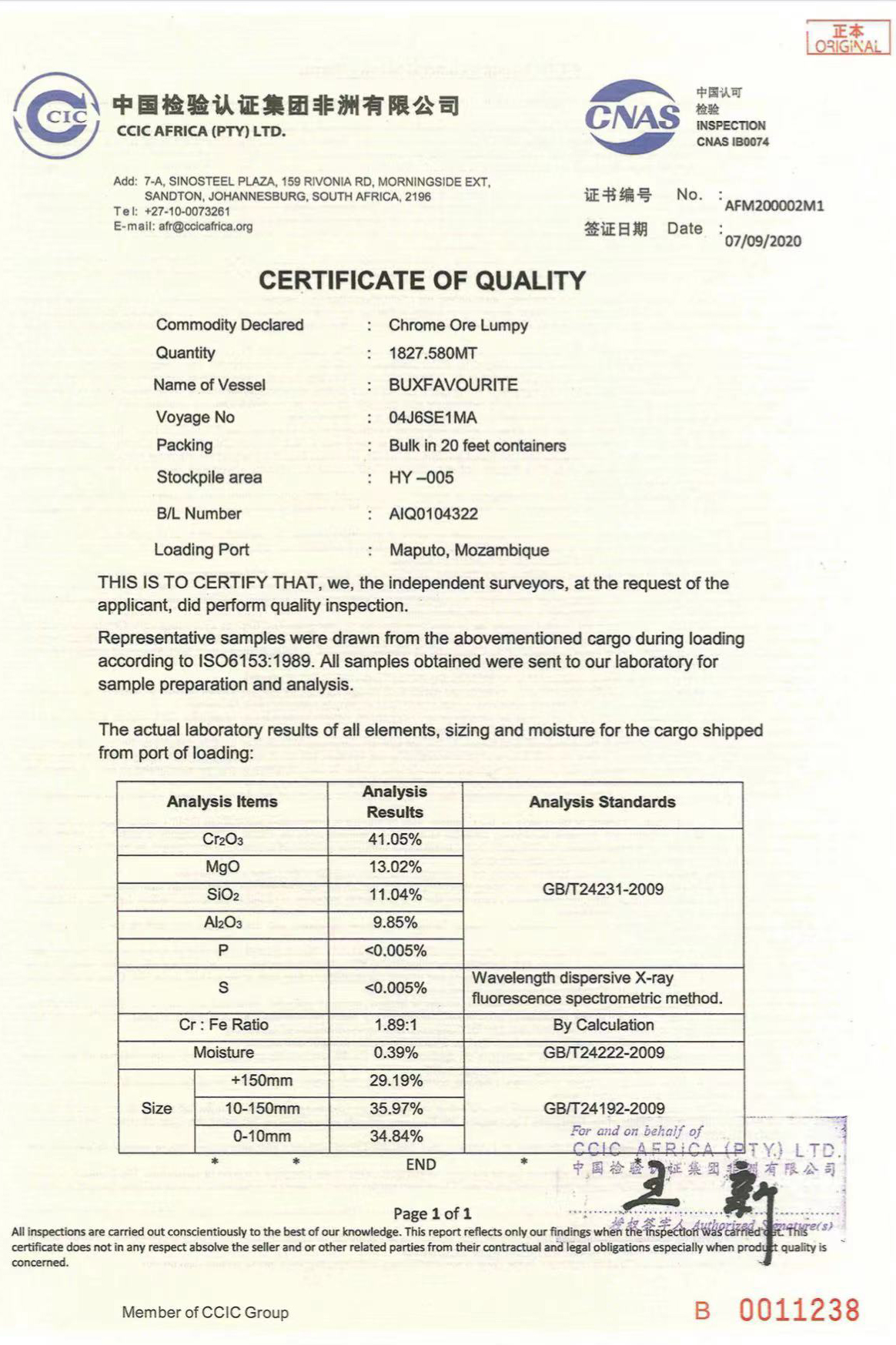

Documents

Rapid Analysis of Chromite and Chrome Ore - USGS

Specification

|

Grade |

Chemical Composition(%) |

|||||

|

Cr |

C |

Si |

P |

S |

||

|

Micro carbon |

Grade 1 |

58-68 |

0.03-0.15 |

1.0-2.0 |

0.03-0.06 |

0.025-0.03 |

|

Grade 2 |

63-68 |

0.03-0.15 |

1.0-2.0 |

0.03-0.06 |

0.025-0.03 |

|

|

Low carbon |

Grade 3 |

58-68 |

0.25-0.5 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

Grade 4 |

63-68 |

0.25-0.5 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

|

Medium carbon |

Grade 5 |

58-68 |

1.0-4.0 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

Grade 6 |

63-68 |

1.0-4.0 |

1.5-3.0 |

0.03-0.06 |

0.025-0.03 |

|

|

High carbon |

Grade 7 |

58-68 |

4.0-10.0 |

3.0-5.0 |

0.03-0.06 |

0.03-0.06 |

|

Grade 8 |

63-68 |

4.0-10.0 |

3.0-5.0 |

0.03-0.06 |

0.03-0.06 |

|

- Loading...